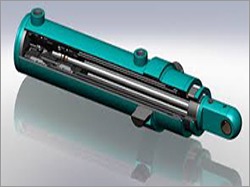

Telescopic Hydraulic Cylinder

Product Details:

- Pressure 160-320 bar

- Capacity Up to 40 Tons

- Temperature -20C to +80C

- Wall Thickness 6-14 mm (Depending on section and length)

- Material High Grade Alloy Steel

- Structure Multistage Telescopic

- Power Hydraulic

- Click to View more

Telescopic Hydraulic Cylinder Price And Quantity

- 1 Piece

- 10000.00 INR/Piece

Telescopic Hydraulic Cylinder Product Specifications

- 50 mm to 200 mm

- 75-180 kg (Varies by model and length)

- Hydraulic

- Multistage Telescopic

- -20C to +80C

- 6-14 mm (Depending on section and length)

- Up to 5 meters or as specified

- 160-320 bar

- Polyurethane/ Nitrile Rubber Seals

- Up to 40 Tons

- High Grade Alloy Steel

- Hard Chrome Plated Steel

- Customizable (Standard lengths from 800 mm to 5000 mm)

Telescopic Hydraulic Cylinder Trade Information

- 50 Piece Per Week

- 3 Days

Product Description

Our company is offering high-quality Telescopic Hydraulic Cylinder that is used in the several mechanical systems which are driven by the hydraulic power. The telescopic cylinder is designed and manufactured at our full-fledged production site, incorporating the lasted machines and tools and therefore, we are capable to supply the optimum quality and functional cylinder. Owing to its unmatched ergonomics, it is easy to install the cylinder on the complex mechanical system. And also, the installation can be carried out within the least possible time period. This superlative Telescopic Hydraulic Cylinder can be availed from us in varied capacities and technical specifications.

Frequently Asked Questions:

1. What is a telescoping hydraulic cylinder?

Ans. Telescopic cylinders are a special layout of a hydraulic cylinder or pneumatic cylinder as well as pulley device which offer a very lengthy output journey from a very compact retracted duration.

2. What is the function of the telescopic cylinder?

Ans. Telescopic cylinder is used in which there is an area constraint. A telescopic cylinder includes a series of rams nested in a telescopic meeting which offers a protracted extension. Such cylinders are beneficial for applications requiring a long stroke but with the best-constrained area to be had for the unextended ram.

3. What are the benefits of a telescopic cylinder?

Ans. Telescopic cylinder advantages

the main advantage of the use of a telescopic hydraulic cylinder is it may be made as single performing, double performing, or one / double-performing mixture.

Advanced Hydraulic Power for Heavy-Duty Applications

Engineered for demanding tasks, our telescopic hydraulic cylinders deliver unmatched strength and efficiency. Whether used in tippers or mobile equipment, each cylinder undergoes a proprietary corrosion-resistant treatment, ensuring longevity even in harsh environments. The multistage design guarantees compact retraction and extended reach.

Custom Mounting and Dimensional Flexibility

Choose from Clevis, Trunnion, Flange, or customized mounts for seamless integration into your machinery. With bore options ranging from 80 mm to 250 mm and extended lengths of up to five times the retracted dimension, our cylinders are tailored to meet project-specific requirements.

Reliable Performance Across Temperatures

Our hydraulic cylinders operate efficiently between -20C and +80C, using mineral or synthetic hydraulic oils as working mediums. The robust structure and precision-engineered seals help maintain performance and durability over years of usage.

FAQs of Telescopic Hydraulic Cylinder:

Q: How do I select the correct telescopic hydraulic cylinder configuration for my application?

A: To choose the right configuration, consider the required lifting capacity, stroke length, mounting type (Clevis, Trunnion, Flange, or Custom), and operating pressure. Our engineering team can assist by evaluating your equipment specifications, such as bore size, number of stages, and application environment.Q: What surface treatments are used to ensure corrosion resistance?

A: Each cylinder undergoes high-quality corrosion-resistant painting or coating processes. This treatment extends the components lifespan and maintains performance even in rugged outdoor or industrial conditions, making them ideal for tippers, dumpers, and mobile equipment.Q: When is it advisable to specify custom mounts or dimensions?

A: Custom mounts and dimensions are recommended when standard options do not fit existing equipment or when unique architectural, space, or load constraints are present. Our design team will work with you to deliver a cylinder precisely manufactured to your operational needs.Q: Where are these telescopic hydraulic cylinders typically utilized?

A: These cylinders are primarily installed in tipping vehicles, dump trucks, off-road and mobile machinery, and industries requiring heavy-duty, long-stroke lifting. Theyre suitable for Indian and global market requirements as supplied by our manufacturing and service divisions.Q: What is the process for ordering a customized hydraulic cylinder?

A: The process begins with a consultation to gather details such as the application, load rating, required stroke, mounting preferences, and operation conditions. Once specifications are finalized, manufacturing is carried out to strict quality standards, followed by testing before delivery.Q: How should I maintain and care for the telescopic hydraulic cylinder?

A: Regular inspection of seals, monitoring hydraulic oil quality, and checking for external wear or corrosion are vital. Ensure proper system filtration to avoid contamination, and follow the manufacturers recommended maintenance schedule to maximize lifespan and performance.Q: What are the key benefits of choosing a multistage telescopic hydraulic cylinder?

A: Multistage cylinders offer compact retraction and extensive extension, enabling greater lift distances from a smaller initial footprint. This provides increased efficiency, adaptability to various machinery, and optimized use of installation spaceessential for mobile and heavy-duty operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+