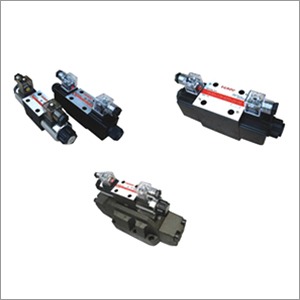

Operated Direction Control Valves

Product Details:

- Product Name Operated Direction Control Valve

- Type Hydraulic/Manual/Pilot operated

- Material High-grade Cast Iron/Steel

- Power Manual/Hydraulic/Electric

- Pressure Up to 315 bar (4570 psi)

- Structure Spool Type, Modular Design

- Size Available in 1/4 inch to 2 inches

- Click to View more

Operated Direction Control Valves Price And Quantity

- 10000.00 INR/Piece

- 1 Piece

Operated Direction Control Valves Product Specifications

- Varies by Model (Approx. 210 kg)

- Available in 1/4 inch to 2 inches

- -20C to +80C

- Operated Direction Control Valve

- Up to 315 bar (4570 psi)

- High-grade Cast Iron/Steel

- Manual/Hydraulic/Electric

- Hydraulic/Manual/Pilot operated

- Spool Type, Modular Design

Operated Direction Control Valves Trade Information

- 50 Piece Per Week

- 3 Days

Product Description

Operated Direction Control Valves that we are offering are widely acclaimed for its ergonomic design, supreme performance, and long functional life. It is easy to install the valve on the mechanical system that requires hydraulic power (power generated from the compressed air) as the design of the valve is pretty user supportive. Moreover, the raw material used in the manufacturing of the valve has been procured from the trusted vendors of the market and is of optimum quality, therefore, the durability and unmatched performance of the valve are ensured. Besides, we have stringently checked the Operated Direction Control Valves based on certain quality parameters, which ascertain the top-notch quality of the offered product.

Frequently Asked Questions:

1. What is the operation of directional control valves?

Ans. A directional control valve consists of an automatically or electrically actuated spool inner a cylinder. The spools' position lets in or prevents fluid glide within the passageway, this frequently happens right away, inflicting fluid to accelerate and slow down hastily.

2. Which valve is used to manipulate the direction?

Ans. Globe valves and needle valves are preferred designs used for flow control. Unidirectional waft manipulates valves to manipulate the float in one path however permits loose go with the flow in a different direction. Pressure-compensated float control valves also are manufactured.

3. What is the maximum not unusual form of directional manage valve?

Ans. The most commonplace directional control valve is a 4/3-way valve, which means the valve has four operating ports and three spool positions. The two-way directional control valve is the simplest directional control valve that has ports called inlet and outlet.

Versatile Configuration for Various Needs

Choose between 2, 3, or 4-port options to suit different hydraulic circuit requirements. The modular design supports both sub-plate and inline installation, providing flexibility for industrial setups and simplifying integration with existing machinery.

Durable Build and Reliable Performance

Constructed with high-grade cast iron or steel, and finished with corrosion-resistant coatings, these direction control valves are engineered to withstand harsh industrial environments. Seal choices of Nitrile (NBR) or Viton allow compatibility with a wider range of fluids, ensuring longevity and leak-free operation.

Operation and Control Methods

A range of operatorsmanual lever, solenoid, or pneumaticenables optimal control for specific applications. Fast response times of less than 20 milliseconds support high-speed automation and efficient machine processes. Options for spring return or detent spool positions further enhance usability.

FAQs of Operated Direction Control Valves:

Q: How do I determine which port configuration is suitable for my application?

A: Select the port configuration based on your systems requirements: 2-port for on/off control, 3-port for basic directional change, and 4-port for complex flow direction in hydraulic circuits. Consulting your system schematic or a hydraulic engineer can guide optimal selection.Q: What mounting options are available for these valves and how do I decide between them?

A: Operated Direction Control Valves offer sub-plate and inline mounting. Sub-plate mounting is ideal for modular systems or multiple valve arrangements, while inline mounting suits direct integration along piping. Consider space, flexibility, and maintenance requirements for your choice.Q: When should I choose Nitrile (NBR) or Viton seals for my valve?

A: Nitrile (NBR) seals are recommended for standard hydraulic oils and applications operating within moderate temperature ranges. Viton seals offer enhanced chemical resistance and withstand higher temperatures, making them suitable for aggressive fluids or harsher environments.Q: Where are these direction control valves typically used?

A: These valves are widely employed in industrial hydraulic systems, machine tools, and construction equipment across India and globally. Their robust design makes them suitable for both stationary and mobile machinery in demanding conditions.Q: What is the process for servicing or replacing a valve in an existing hydraulic system?

A: Depressurize the hydraulic circuit, disconnect port connections, and remove mounting hardware. Installation of a new valve follows reverse steps, ensuring compatibility with port sizes, seals, and mounting type. Always comply with manufacturer and safety guidelines during maintenance.Q: How does the fast response time benefit my hydraulic application?

A: With response times under 20 ms, these valves provide swift flow control, reducing cycle times in automated machinery. Quick actuation supports high-speed operations, enhancing overall system efficiency and productivity.Q: What advantages does the corrosion-resistant surface finish provide?

A: The protective finish shields internal and external components from wear and environmental corrosion, extending valve service life and reliability in harsh or outdoor conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free