Hydraulic Component Design Consultants

Product Details:

Hydraulic Component Design Consultants Price And Quantity

- 1 , , Piece

Hydraulic Component Design Consultants Trade Information

- 1 , , Piece Per Day

- 1 Days

Product Description

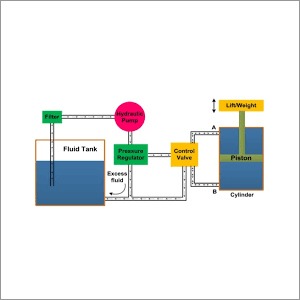

The offered Hydraulic Component Design is made available by us for use in various places that want to install or change the existing hydraulic system. The offered designs are made available by thorough professionals and are very efficient. Regardless of its function and design, every hydraulic system has a minimum number of basic components in addition to a means through which the fluid is transmitted. The offered Hydraulic Component Design helps in making the hydraulic system work very effectively and also very easy to install. The design is very up to date and has the location of the various components.

Frequently Asked Questions:

1. What does a hydraulic consultant do?

Ans. What are hydraulic services consulting? Plumbing design is finished via hydraulic consultants, who lay out and record plumbing offerings for buildings. Those offerings are a vital part of the construction as they include the delivery and disposal of liquids and gases throughout the construction.

2. What are the 4 most important components of hydraulic structures?

Ans.The principal additives that make up a hydraulic gadget are the reservoir, pump, valve(s) and actuator(s) (motor, cylinder, etc.).

3. What are the 6 primary additives required to build a hydraulic system?

Ans. The main additives of a hydraulic system are

(i) hydraulic pump, (ii) reservoir for hydraulic fluid, (iii) filter out, (iv) actuator, (v) accumulator, (vi) directional manipulate valve, (vii) waft control valve, (viii) strain remedy valve, and (ix) pipes and fittings.

Comprehensive Hydraulic Design Expertise

Our team combines practical know-how with advanced simulation and CAD software to streamline the design and integration of hydraulic components for a diverse range of applications. Solutions are customized for industrial, mobile, and specialized machinery to meet client-specific requirements while optimizing system performance and reliability.

Robust Project Management and Documentation

Clients receive thorough support throughout the project lifecycle, with detailed design files, performance analyses, and comprehensive reports that promote transparency, traceability, and seamless integration. NDAs are available for enhanced confidentiality, ensuring the secure handling of proprietary information.

Flexible Consultancy Engagements

Whether requiring on-site technical guidance or remote design support, our consultancy adapts to unique project scopes and timelines. Engagements can be structured as short-term projects or retainer relationships to best serve manufacturers, OEMs, system integrators, and suppliers seeking hydraulic engineering excellence.

FAQs of Hydraulic Component Design Consultants:

Q: How do Hydraulic Component Design Consultants approach custom hydraulic system design?

A: We begin with a detailed analysis of client requirements and specifications, then use advanced CAD and simulation tools to design components including valves, pumps, actuators, and manifolds. Our process incorporates system integration and troubleshooting to deliver custom, high-performance solutions tailored to industrial, mobile, or specialized machinery.Q: What types of hydraulic systems and components can you design and support?

A: Our consultants are experienced in designing and developing industrial, mobile, and custom machinery hydraulic systems. We handle a variety of components, such as valves, pumps, actuators, and manifolds, ensuring compliance with international standards.Q: When can I expect to receive project deliverables and documentation?

A: Project timelines and documentation delivery are determined based on the agreed scope and complexity of each engagement. Clients receive detailed design files, performance analyses, and comprehensive reports at defined milestones and upon project completion.Q: Where are your consulting services available, and do you offer remote support?

A: We serve clients throughout India and provide both on-site and remote consultancy options to accommodate diverse project needs. This flexibility ensures timely technical and project management support, regardless of location.Q: What is the consultancy engagement process with your team?

A: Our process typically starts with a client meeting to define project goals, followed by a proposal outlining deliverables, timelines, and confidentiality terms including NDAs if required. The project proceeds with design, documentation, reviews, and final submission, supported by ongoing communication and troubleshooting.Q: How can your consultancy benefit manufacturers and system integrators in hydraulic engineering?

A: Clients gain access to specialized expertise in system integration, troubleshooting, and custom hydraulic solutions, bolstered by thorough documentation and performance analysis. Our services reduce development cycles, enhance product reliability, and support compliance with international standards.Q: Do you follow any specific standards for hydraulic component design?

A: Yes, all our designs and solutions strictly adhere to established international hydraulic standards to ensure safety, compatibility, and performance across every project.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+